What Are Hex Self Drilling Screws? A Beginner’s Guide

Fasteners are a pivotal element in manufacturing and PEB, providing security and integrity to structures. Among other fasteners, hex self drilling screws is a new-age solution, simplifying assembly stages and maximizing effectiveness.

This guide is prepared to offer a holistic overview of hex washer head self drilling screw, understanding their design, operation, benefits, and uses.

What Are Hex Self Drilling Screws?

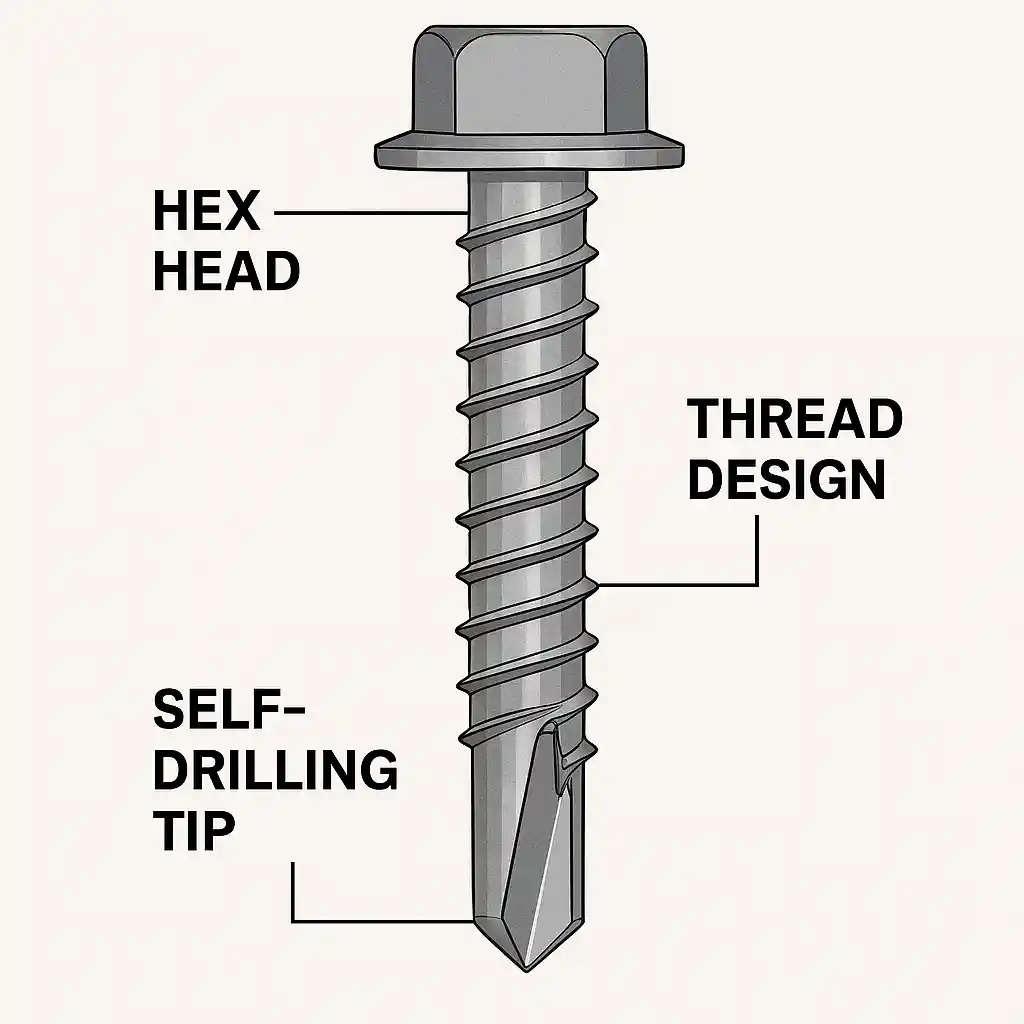

Hex self drilling screws that are specially specialized for fasteners that drill their own pilot hole and create mating threads in a single operation. “Hex” describes the six-sided head, which enables simple driving using a wrench or socket.

Key Characteristics:

- Hex Head: Offers a large bearing surface and enables greater torque application without being revealed.

- Self-Drilling Tip: Avoids pre-drilling, conserving time and minimizing the number of tools needed.

- Thread Design: Engineered to tap into materials, ensuring a secure hold.

Unlike conventional screws that need a pilot hole, hex washer self drilling screw integrate drilling and fastening into one step, and for this reason, they are extremely useful in metal-to-metal applications.

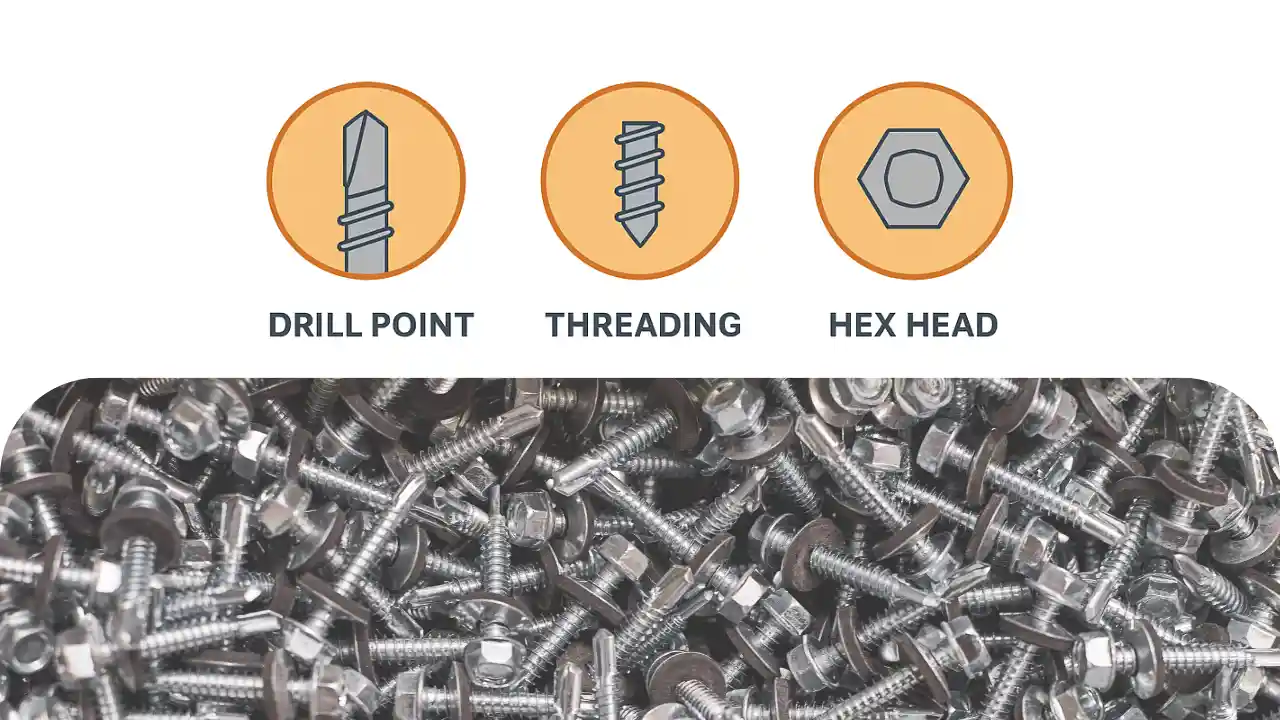

How Do Hex Self Drilling Screws Work?

The efficiency of hexagon self drilling screws lies in their unique design:

- Drill Point: The tip look like a drill bit, enabling the screw to drive into metal surfaces without a pilot hole.

- Threading: As the screw advances, its threads strike the material and form a snug hold.

- Hex Head: Allows for the application of greater torque, ensuring the screw seats properly.

Common materials used in manufacturing these screws include:

- Steel: Contributes to strength and toughness.

- Stainless Steel: Provides corrosion resistance, perfect for outdoor works.

- Zinc-Plated Steel: Combines strength with a protective coating to resist rust.

This integration of drilling and fastening simplifies installation, especially in metal fabrication and construction.

Key Features

Understanding the components of hexagon self drilling screws enhances their effective application:

- Hex Head: shape maintains compatibility with common tools and permits the application of more torque.

- Drill Point Numbers: Refers to the thickness of metal that the screw is able to drill through:

- #1: Thin metals.

- #2: Medium thickness.

- #3 to #5: Heavy metals, with #5 able to drill 0.5 inches of steel.

- Thread Design: Specifically designed to make metal fastening stronger and durable grip.

- Corrosion Resistance: Zinc plating and galvanization are available options to increase the life of screws in various environments.

With these features, hexagon self drilling screws are versatile and dependable for many applications.

Advantages of Using Hex Head Self Drilling Screws

Utilizing stainless steel hex head self drilling screws presents various advantages:

- Time and Labor Cost Savings: Eliminates pre-drilling, accelerating installation.

- Strong & Solid Grip: Constructed for metal-to-metal installation, guaranteeing structural stability.

- High-Torque Applications: Hex head permits more torque, with a lower risk of stripping.

- Clean Finish: Offers a neat, professional look, critical in installations with visibility.

These benefits make them the choice in construction, manufacturing, and DIY.

Common Applications

Hex self drilling screws are broadly used across various industries:

- Roofing and Cladding: Secure metal sheets and panels efficiently.

- HVAC Installations: Good for the assembly of ductwork and mounting units.

- Steel Framing and Metal Fabrication: Essential in framing structures and buildings.

- Automotive and Industrial Use: Applied in machinery and vehicle assembly.

Their strength and versatility render them a necessity where there’s a need for dependable metal fastening.

Tips for Beginners

For beginners who are new to using of hex head self drilling screws, the followings are considered:

- Selecting the Right Size: Enhance the screw length and diameter according to the thickness of the material and application.

- Tool Suitability: Employ proper tools such as impact drivers or hex socket drills to minimize installation time.

- Avoid Overdriving: Stop once the screw is flush to prevent stripping or damaging the material.

- safety measures: Always wear eye protection and work gloves to prevent injuries.

Following these guidelines guarantees a successful and safe installation process.

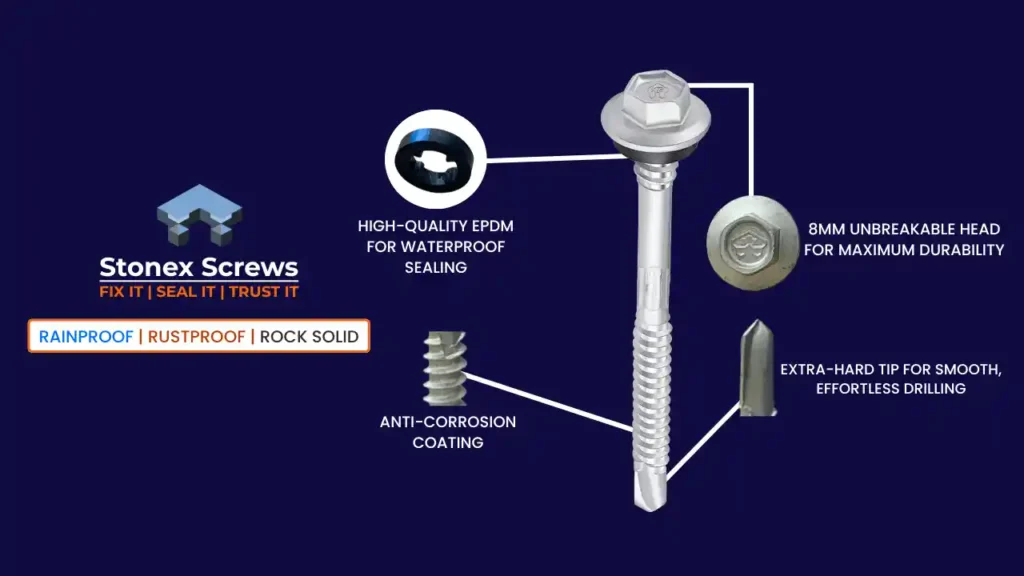

Why Professionals Choose Stonex Screws

Stonex Screws have earned a reputation among professionals for quality and dependability:

- Premium Materials: Made from high-grade material for strength.

- Corrosion Resistance: Equipped with coatings that resist severe conditions.

- Efficient Design: Designed to easily penetrate and fasten securely.

- Bulk Order Options: Available in various quantities to suit huge project needs.

Professionals trust Stonex Screws for their consistent performance and value.

Hex head self drilling screws transform fastening metal applications by drilling and threading in a single action. Their structure is designed for strength, efficiency, and tidy finish, and making them a first preference choice for both professionals and DIYers.

Ready to take your next project to the advanced level? Check out our entire hex self drilling screws range and discover the difference in quality and performance.

FAQ

It refers to the six sided head shape, which provides greater torque application through a hex driver or socket.

They work best with metal, steel, aluminum, and occasionally hard plastic. They’re used a lot in construction and fabrication.

No, the integral drill tip negates the need for a pilot hole, so installation is quicker.

They are made for metal-to-metal or metal-to-wood use, but when dealing with wood-only projects, wood screws will typically suffice.

A power drill or impact driver with a hex socket bit is commonly used.