Self Drilling Screw VS Self Tapping Screw: Which One is Best?

When you are choosing between self drilling screw vs self tapping screw, understanding its differences is key. Both help you save time compared to normal screws, but they used for different purposes. Use the right screw and you will improve build quality, reduce labor, and avoid expensive damages.

If you are not certain of self drilling vs self tapping screws, this article will guide you. And we primarily talk of primary differences, where one is best used, and which one is best for you. You will learn when to use self drilling screws for steel, when self drilling roofing screws are perfect, and when STS are the better choice.

By the end, you’ll know:

- What makes self drilling screw vs self tapping special

- Benefits of self drilling metal screws and self drilling screws for thick steel

- When self drilling vs self tapping screw affects speed

- Answers to FAQs like “Where can I find self drilling screws?”

Ready to make the better decision? Keep reading to dive deeper into essential variation, applications, and expert tips.

What’s the Difference Between Self Drilling and Self Tapping Screws?

It is important to know the difference between self tapping and self drilling screws. Here you can see the comparison between self drilling screw vs self tapping screw for any project.

- Hex self drilling screws have drill-like tip that drive holes, cut threads, and fasten all in one single action. This saves time and work when drilling on metals like steel or using as self drilling roofing screws.

- Self tapping screws are always need a pilot hole first. They don’t drill, but they can cut threads into the pre-drilled hole, making them easier for wood, plastic, and lighter gauge metals.

Key differences at a glance:

- Pilot hole needed?

- Self drilling screws – no

- Self tapping screws – yes

- Speed of installation:

- Self drilling screw vs self tapping screw, drilling tips speed up the process, while self tapping screws require extra steps.

- Best materials:

- Self drilling screws for steel, self drilling metal screws, self drilling screws for thick steel

- STS – wood, lighter gauge or pre-punched holes

- Cost & strength:

- Self drilling vs self tapping screw: drilling screws cost more but offer stronger, quicker fastening. STS cost less but need careful pilot hole sizing.

By understanding the breakdown of self drilling screw vs self tapping screw, you’ll no longer be confused or wonder, ‘Is self drilling the same as self tapping screws?’

Self Drilling Screws

If you want fast, strong fastening in metal or roofing, self drilling screws are unbeatable. Here’s why applications like self drilling roofing screws and self drilling screws for thick steel are ideal.

Self drilling screws come with a built-in drill tip—no need for pilot holes. This makes them excellent for metal-to-metal fastening or roofing sheeting. They’re common in:

- Metal framing: self drilling screws for steel, self drilling metal screws

- Thick materials: self drilling screws for thick steel

- Roofing: self drilling roofing screws with sealing washers

Benefits:

- One-step process: drill, tap, and fasten in a single go

- Faster installation than self tapping screws

- Clean, dependable threads in metal applications

- Durable across various gauge steels (choose #1–#5 drill point)

Best Practices:

- Choose the right tip size for your material thickness

- Use center-punches to avoid tip wandering

- Apply correct torque to prevent thread stripping

Remember, when combining self drilling vs self tapping screw, drilling screws offer speed and ease—but cost slightly more. For jobs requiring fast, secure fixings—especially metal—they are the clear winner.

Now that you know why self drilling screws excel in strength and speed, let’s focus on when self tapping screws are the better choice.

Self Tapping Screws

Not every project requires a drill-tip screw. Here’s why self tapping screws shine when working with softer materials, pre-drilled holes, or applications needing precision.

Self tapping screws need pilot holes. They tap their own threads into materials like wood, plastic, or thin-sheet metals. Use them where groove precision matters:

- Wood framing and trim installation

- Plastic enclosures and panels

- Light-gauge sheet metal, electrical mounts

Advantages:

- Excellent control when working with delicate materials

- Cost-effective and widely available

- Variety of thread profiles and head types

Considerations:

- If the pilot hole is too small, it can crack the material; if it’s too large, the screw may not hold securely.

- Slower than single-step self drilling screws

- Doesn’t handle thick metal—opt for self drilling screws for steel instead

Tips:

- Use sharp drills and pilot guides

- Match screw type to material and hole diameter

- Keep consistent torque to avoid stripping

When weighing self drilling screw vs self tapping screw, the choice is clear: choose STS for accuracy, control, and soft-material applications.

With both screw types understood, here’s a quick recap to help select between self drilling vs self tapping screws based on your needs.

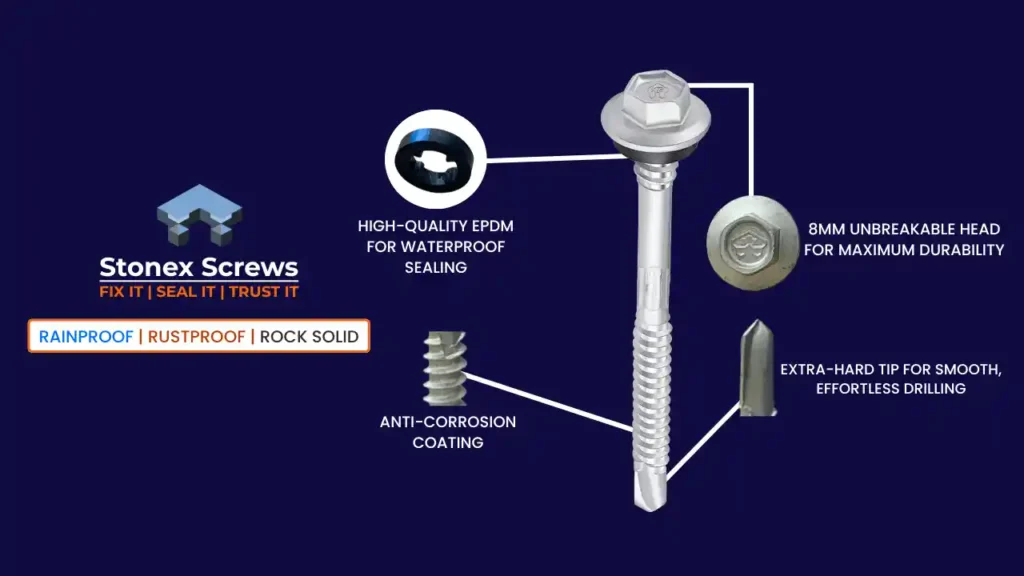

Why Choose Stonex Screws?

Self drilling screw vs self tapping screw: the correct screw can be a game-changer—but so can the brand. Stonex Screws exclusively specializes in self drilling screws, offering unbeatable quality and performance for metal, roofing, and heavy-duty usage.

Stonex Screws is trusted by engineers, contractors, and fabricators in multiple industries for a reason: we do one thing and we do it to the best of our ability—self drilling screws.

Here’s why professionals choose Stonex:

- Expert Design: Each Stonex self drilling screw has a drill point of high precision that drives through steel without pilot holes—saves labor and time.

- Reliable Strength: Our screws are perfect for tough applications, such as self drilling screws for thick steel.

- Faster Installation: One-step fastening means greater efficiency on-site.

- Corrosion Resistance: Made to resist tough environments, our screws are coated for long-term protection.

- Expert Design: Each Stonex self drilling screw has a drill point of high precision that drives through steel without pilot holes—saves labor and time.

Unlike self tapping screws, where pre-drilling is a must, Stonex self drilling screws are all set—making them the superior option when self drilling vs self tapping screws is compared on the basis of speed and strength.

If your project requires high-quality self drilling screws for steel, select Stonex Screws—designed for excellence, engineered to last.

Conclusion

So, which is the best between self drilling screw vs self tapping screw? The answer depends on your materials, needs, and workflow priorities.

- Speed Projects & Thick Metals: Go with self drilling screws—no pilot hole needed, fast installation, strong hold. Ideal for applications like metal roofing, steel framing, and projects that require self drilling roofing screws.

- Soft Material & Precision Work: Choose self tapping screws—they tap neatly into existing holes. Ideal for woodworking, plastics, light metal, and scenarios using self tapping screws thread sizes.

Key Takeaway Table:

Use Case | Recommended Screw Type |

Metal-to-metal, roofing, thick steel | Self drilling screws |

Wood, plastic, precise hole sizes | Self tapping screws |

Mixed material applications | Combine both in one project |

Final Advice:

- Use drill-tip selection: e.g., self drilling screws for thick steel – use #5 tip

- Pre-drill for self tapping screws , ensuring pilot hole matches screw diameter

- Keep torque balanced and maintain cleanliness around screw areas

- Use drill-tip selection: e.g., self drilling screws for thick steel – use #5 tip

Understanding self drilling vs self tapping screw lets you choose smartly. Make your next project efficient, reliable, and professional.

FAQ

Self drilling screws drill, tap, and fasten together in one single action, saving effort and time. They are perfect for metal-focused applications such as steel framing, roofing, or HVAC installation. Their built-in drill-tip prevents the need for separate holes and reduces tool switching—making them stronger and faster for metal applications.

You can buy self drilling screws from Stonex Screws at an affordable price with premium Taiwan quality. We offer reliable options for steel, roofing, and thick metal applications. Trust Stonex for fast, durable fastening solutions designed for professionals who demand performance, precision, and value in every screw.

No. Although self drilling screws are technically self tapping screws since they form threads, they are different in that they possess a drill tip and do not need a pilot hole. On the other hand, self tapping screws require pre-drilling and lack a drilling tip in their construction.

Yes! Self drilling metal screws are designed specifically for metal applications like steel framing, metal roofing, HVAC systems, and general construction. Utilize types such as self drilling screws for thick steel with the correct drill-point (e.g., #5) for metals up to ½″ thick for solid, reliable fastening.