High-Performance Self-Drilling Screws for Modern Construction & Metal Fabrication | Stonex India

Compared to the construction and engineering industries of today, demand for durable, high-strength fasteners has never been higher. From metal roofing and structural steelwork to industrial machinery and precision fabrication, one fastener stands out because of its strength, efficiency, and reliability: the self-drilling screw.

At Stonex Screws, one of the leading self-drilling screw manufacturers in India, we specialise only in top-of-the-range quality self-drilling solutions for heavy-duty applications. Our screws are engineered to deliver clean penetration, excellent holding power, and long-lasting performance in demanding environments.

From this comprehensive guide, you will learn all that you need to know about self-drilling screws, how they vary from self-tapping screws, and why industries have come to rely on Stonex for superior fastening solutions.

1. What Are Self Drilling Screws?

Self-drilling screws are advanced fasteners equipped with a drill-bit tip that allows them to drill, tap, and fasten in one continuous motion. This means you don’t need a pilot hole — saving both time and labour.

These screws are essential in:

- Metal roofing structures

- Steel fabrication

- Industrial installation

- Automotive metal components

- Mechanical assemblies

- Pre-engineered buildings (PEB)

Unlike normal screws, self-drilling screws are designed to pierce through hard metals clean and efficiently, hence preventing any kind of damage to the surface of metals. This advantage reduces the risk of screw damage and improves structural stability.

2. Self-Drilling Screws vs. Self-Tapping Screws (Important Difference)

Many people confuse self-tapping screws with self-drilling screws. While both are used in various industries, they serve different purposes.

✔ Self-Drilling Screws

- Drill and tap threads simultaneously

- Ideal for metal-to-metal connections

- No pre-drilling needed

- Perfect for heavy-duty applications

✔ Self-Tapping Screws

- Require a pilot hole

- Create internal threads, but do not drill

- Used in lighter materials like plastic or wood

Stonex manufactures only self-drilling screws, but we include comparisons to help buyers choose the right fastener for their application.

3. The Power of Hex Head Self-Drilling Screws

One of the strongest variations in the industry is the hex head self drilling screw. With its six-sided hex screw head, it provides superior grip, making it ideal for high-torque fastening.

Applications include:

- Metal roofing

- Cladding sheets

- Structural steel beams

- Industrial machinery

- Outdoor frameworks

At Stonex, our hex head screws are built with corrosion-resistant coatings to withstand extreme weather conditions, making them top-performing metal roofing fasteners.

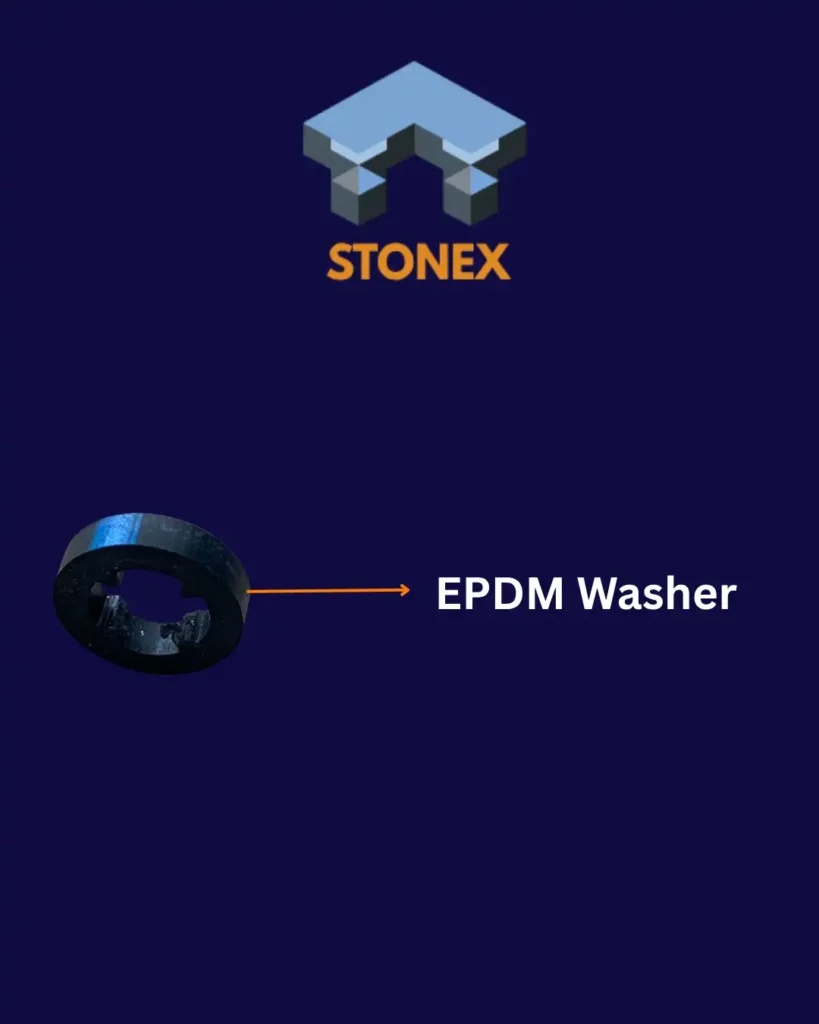

4. Screws With EPDM Washers: Enhanced Sealing & Stability

Many roofing and cladding applications require screws with an EPDM washer or screws and EPDM washer combinations.

The washer helps:

- Distribute pressure evenly

- Prevent leaks

- Avoid material deformation

- Provide secure long-term fastening

These are especially important in roofing projects exposed to wind, rain, and high temperature variations.

5. Advanced Self Drilling Fasteners Manufactured by Stonex

As a leading screw company and reliable name in the fasteners industry, Stonex offers a complete range of specialised self-drilling screws, including:

✔ Hex Head Self-Drilling Screws

For metal roofing, steel sheets & industrial assemblies.

✔ Double Threaded Self-Drilling Screws

Improved grip for high-strength applications.

✔ Precision Self-Drilling Screws

For fabrication, machinery, and high-accuracy fastening.

✔ Self-Drilling Screws With EPDM Washers

Perfect sealing for roofing jobs.

All products are built with premium materials and top-tier screws packaging for safe transportation.

6. Why Stonex Is the Trusted Name for Self Drilling Screws in India

With a strong focus on innovation and quality, Stonex is quickly establishing itself as a trusted name in self-drilling screw manufacturing.

✔ High-strength, corrosion-resistant materials

✔ Precision-made screw thread quality

✔ Advanced manufacturing technology

✔ Consistent product accuracy

✔ Bulk production expertise

✔ Dedicated quality testing

Our product range supports small workshops, large engineering companies, construction contractors, and metal fabrication units across India.

7. Common Uses of Self Drilling Screws in Modern Industries

Construction & PEB Structures

Metal beams, angles, purlins, rafters, and frames.

Metal Roofing & Cladding

Colour-coated sheets, aluminium panels, metal roofing fasteners.

Automotive and Machinery

Body parts, mechanical assemblies, frames.

Industrial Engineering

Equipment installation, ducting, and heavy fabrication.

Home and Commercial Installations

Signboards, AC units, light metal structures.

8. Choosing the Right Self Drilling Screw

Follow these steps:

✔ Choose the correct head type

Hex head for roofing

Pan head for general use

Countersunk for flush surfaces

✔ Select the right length

This prevents over-penetration or weak fastening.

✔ Pick corrosion-resistant coatings

Essential for outdoor or marine environments.

✔ Ensure compatibility

Match screw size with your metal thickness.

✔ Buy from a reliable manufacturer

Avoid structural failures by choosing Stonex — a trusted fasteners manufacturer.

FAQ

Yes, self-drilling screws are among the best options for metal roofing applications. The inbuilt drill tip gives them the ability to make clean penetration into the roofing sheets and the metal purlins without prior drilling. This makes the installation process faster and hence reduces the labour effort involved, while providing a strong and reliable hold.

In fact, hex head self-drilling screws are common for best performance due to their good grip, excellent torque resistance, and long-term durability even under harsh outdoor conditions. These qualities make self-drilling screws the most dependable metal roofing fasteners in both residential and industrial roofing systems.

No, self-drilling screws are engineered in a way that no screw damage will occur. The drill-bit tip allows for smooth penetration, reducing the possibilities of screw head slipping, bending, or stripping. Because they drill and tap in one continuous action, the material isn’t subjected to stress due to multiple changes of tools or uneven pressure. Such risks as cracking of the sheet, thread stripping, or damage to the screw tip are reduced. Self-drilling screws provide long-lasting structural integrity if correctly installed with appropriate tool speed.

The main difference refers to the way these screws prepare the material:

- Self-tapping screws require a pilot hole. They cannot drill through metal themselves; they form internal threads only when one prepares an entry hole.

- By contrast, self-drilling screws have a drill-shaped tip that eliminates the need for pre-drilling. One-step drilling, tapping, and fastening can be achieved with them.

The advantage, with self-drilling screws for users dealing with metal structures, roofing sheets, or steel fabrication, is that they save time and reduce tool usage, thus providing cleaner and stronger fastening.

At Stonex, only premium-quality self-drilling screws are manufactured for these applications.

Yes, Stonex does manufacture self-drilling screws with high-quality EPDM washers. These washers have several functions:

- They offer a watertight seal, especially important in roofing and outdoor installations.

- They protect the surface from pressure damage when fastening.

- They reduce vibration and prevent loosening over time.

- They improve overall durability in areas exposed to rain, heat, and dust.

In the case of metal roofing, using screws with EPDM washers offers long-term leak protection and resistance to wear from environmental elements.

Although Stonex is still a growing company, we maintain complete readiness to handle bulk orders received from construction companies, distributors, contractors, and industrial clients across India.

We follow a streamlined production and packing process to ensure consistency in quality, timely delivery, and reliable stock availability. Whether the needs are in thousands or lakhs, we can easily supply them according to project timelines and specifications, hence making us a dependable partner in the fasteners industry.

Yes. All of our Stonex self-drilling screws are treated with first-grade anti-corrosion coatings, which provide excellent protection against rust, moisture, and environmental exposure.

These coatings are suitable for:

- outdoor metal structures

- roofing sheets

- industrial equipment

- coastal or high-humidity regions

Rust-proofing for long service life prevents weakening of the structure, keeping the installations safe and secure for years to come.