How to Identify Fake or Sub-Standard Self-Drilling Screws in the Indian Market

In India’s fast-growing construction and manufacturing sector, self-drilling screws are everywhere — from steel buildings and roofing systems to solar structures and industrial sheds. Yet one uncomfortable truth rarely discussed openly is this:

A large percentage of screw failures in Indian projects are caused by fake or sub-standard fasteners.

These screws may look identical at first glance, but the damage they cause over time can be massive — corrosion, breakage, loosening, structural weakness, and costly rework.

This guide explains how to identify fake or low-quality self-drilling screws in the Indian market, even before installation.

Why Fake Self-Drilling Screws Are a Growing Problem in India

The Indian fastener market is highly price-sensitive. This has led to:

- Unorganised manufacturing

- Rebranding of low-grade screws

- Inconsistent raw materials

- No proper quality testing

- Fake coating claims

Many buyers unknowingly choose cheap self-drilling screws, assuming all screws are the same. Unfortunately, they are not.

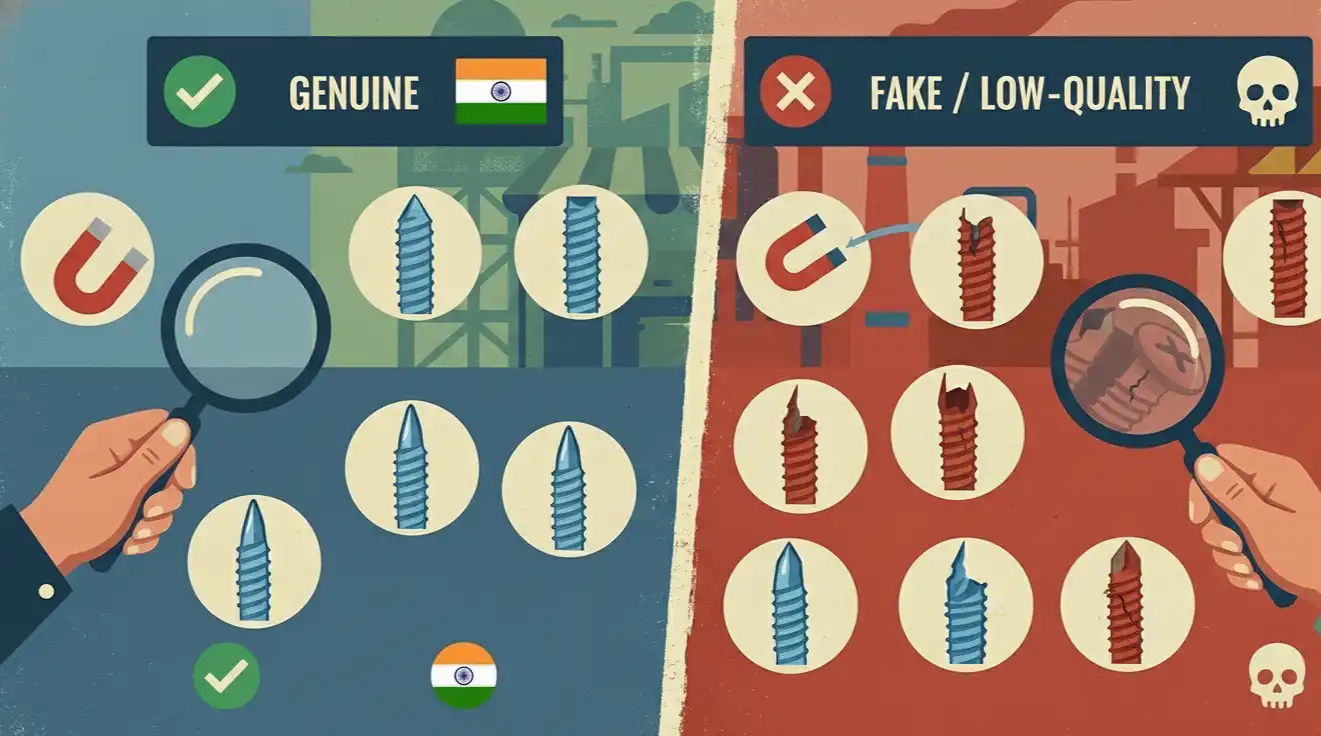

What Are Fake or Sub-Standard Self-Drilling Screws?

Fake or sub-standard screws usually suffer from one or more of these issues:

- Incorrect steel grade

- Poor heat treatment

- Inadequate case hardening

- Thin or cosmetic coating

- Improper drill point geometry

- No torque or corrosion testing

They may pass visual inspection but fail under real load and weather conditions.

10 Practical Ways to Identify Fake or Low-Quality Self-Drilling Screws

1. The Drill Point Test (Most Ignored Red Flag)

A genuine self-drilling screw should drill cleanly into steel without wobbling or burning.

Warning signs:

- Drill point blunts quickly

- Requires excessive pressure

- Produces excessive heat

This indicates poor heat treatment or low-carbon steel.

2. Inconsistent Head Markings or No Branding

Reputed manufacturers maintain consistent head markings for traceability.

Be cautious if:

- Head markings change across batches

- No marking at all

- Random symbols without manufacturer identity

This is common with fake self-drilling screws in India.

3. Coating That Looks Good but Performs Poorly

Many sub-standard screws use decorative coating instead of functional protection.

Signs of fake coating:

- Shiny finish but early rusting

- Flaking after installation

- Rust stains within weeks

Always verify that the screw coating meets the requirements of the Indian climate.

4. Weight Tells the Truth

Low-quality screws are often lighter because of reduced material density.

A simple comparison between two screws of the same size can expose:

- Thinner shank

- Poor thread depth

Weight inconsistency is a strong indicator of sub-standard fasteners.

5. Brittle Screws That Snap Instead of Flex

Over-hardened or poorly treated screws break suddenly under torque.

Quality self-drilling screws are engineered to:

- Withstand torque

- Absorb vibration

- Flex slightly under stress.

If screws snap easily, they are unsafe for structural applications.

6. No Test Certificates or Technical Data

Genuine manufacturers provide:

- Torque values

- Salt spray test results

- Material specifications

If the supplier avoids documentation, it usually means no quality control exists.

7. Unrealistically Low Pricing

If pricing feels too cheap to be true, it usually is.

Cheap self-drilling screws often result in:

- Higher replacement cost

- Increased labor expenses

- Structural risk

- Project delays

Fasteners are small components, but the costs of failure are huge.

8. Packaging Without Batch or Traceability Details

Professional manufacturers use packaging that includes:

- Batch number

- Size details

- Coating type

Unmarked or generic packaging is a common sign of fake fasteners.

9. Poor Performance in Indian Weather Conditions

India’s climate is harsh:

- High humidity

- Coastal salt exposure

- Extreme heat

Fake screws corrode much faster, especially in:

- Coastal regions

- Industrial pollution zones

- Solar installations

10. No After-Sales Accountability

Trusted manufacturers stand by their product.

Fake suppliers disappear when:

- Rust appears

- Screws fail

Audits raise questions

Why Using Sub-Standard Screws Is a Serious Risk

Using fake self-drilling screws can lead to:

- Roof sheet loosening

- Structural instability

- Safety hazards

- Audit failures

- Legal and warranty issues

In many cases, fasteners become the weakest link in an otherwise well-engineered project.

How to Protect Your Project from Fake Self-Drilling Screws

✔ Buy from reputed Indian manufacturers

✔ Ask for technical data sheets

✔ Test samples before bulk use

✔ Match screw specification to application

✔ Choose suppliers with industry experience

FAQ

Identifying a genuine self-drilling screw requires checking both performance and manufacturing quality. A genuine screw should drill smoothly into steel without excessive pressure, vibration, or overheating. The drill point must remain sharp even after multiple uses.

Quality manufacturers like Stonex Screws also maintain consistent head markings, proper thread geometry, and uniform weight across batches. In addition, genuine suppliers are transparent — they can provide test reports, material specifications, and coating details when requested. If a supplier avoids technical questions, it is often a red flag.

In most cases, cheap self-drilling screws are not safe for structural or outdoor construction. Low-cost screws often compromise on steel grade, heat treatment, and corrosion protection to reduce pricing. While they may appear fine during installation, failures usually show up months later.

Professional-grade fasteners such as Stonex Screws are engineered to handle torque, vibration, and long-term exposure. In construction, the cost of screw failure is far higher than the price difference between cheap and quality fasteners.

Not all coatings are designed for real-world performance. Many sub-standard screws use cosmetic coatings that look shiny but provide little protection against humidity, pollution, or salt exposure — especially in Indian climates.

High-quality manufacturers like Stonex Screws use functional corrosion-resistant coatings that are tested for durability in harsh conditions. Rust appearing within weeks or months is usually a sign of poor coating quality or incorrect coating selection for the application.

Fake or sub-standard self-drilling screws commonly suffer from:

- Early corrosion

- Snapping or cracking during installation

- Poor drilling ability

- Reduced holding strength

These issues often stem from poor heat treatment, incorrect steel composition, and a lack of quality control. Reputed brands like Stonex Screws focus on controlled manufacturing processes to ensure consistent performance across every batch.

Fake fasteners may seem economical at purchase, but they significantly increase long-term project costs. Early failures lead to frequent replacements, higher labour expenses, downtime, maintenance issues, and sometimes structural safety risks.

Many contractors eventually discover that investing in reliable fasteners such as Stonex Screws results in lower overall costs, fewer failures, and better project longevity.

India’s climate demands screws that can handle high humidity, extreme heat, industrial pollution, and coastal salt exposure. The best self-drilling screws for Indian conditions are those with tested corrosion resistance, proper heat treatment, and controlled manufacturing standards.

Manufacturers like Stonex Screws design their self-drilling screws specifically to perform in Indian environments, making them suitable for roofing, steel structures, solar installations, and industrial applications.